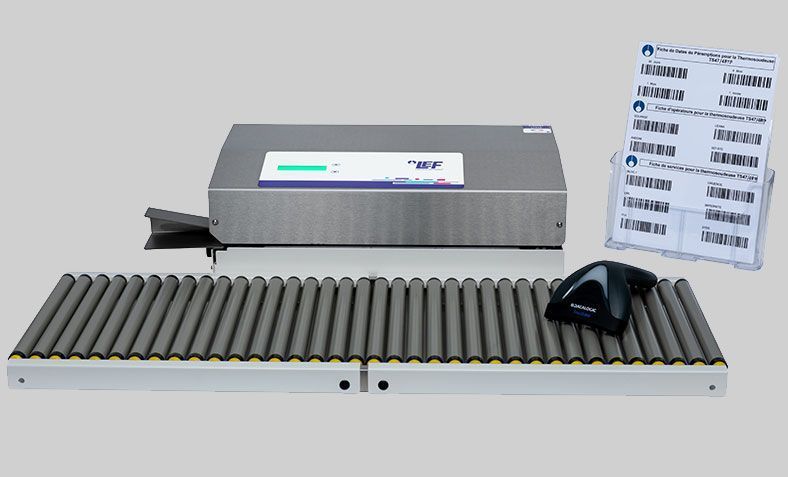

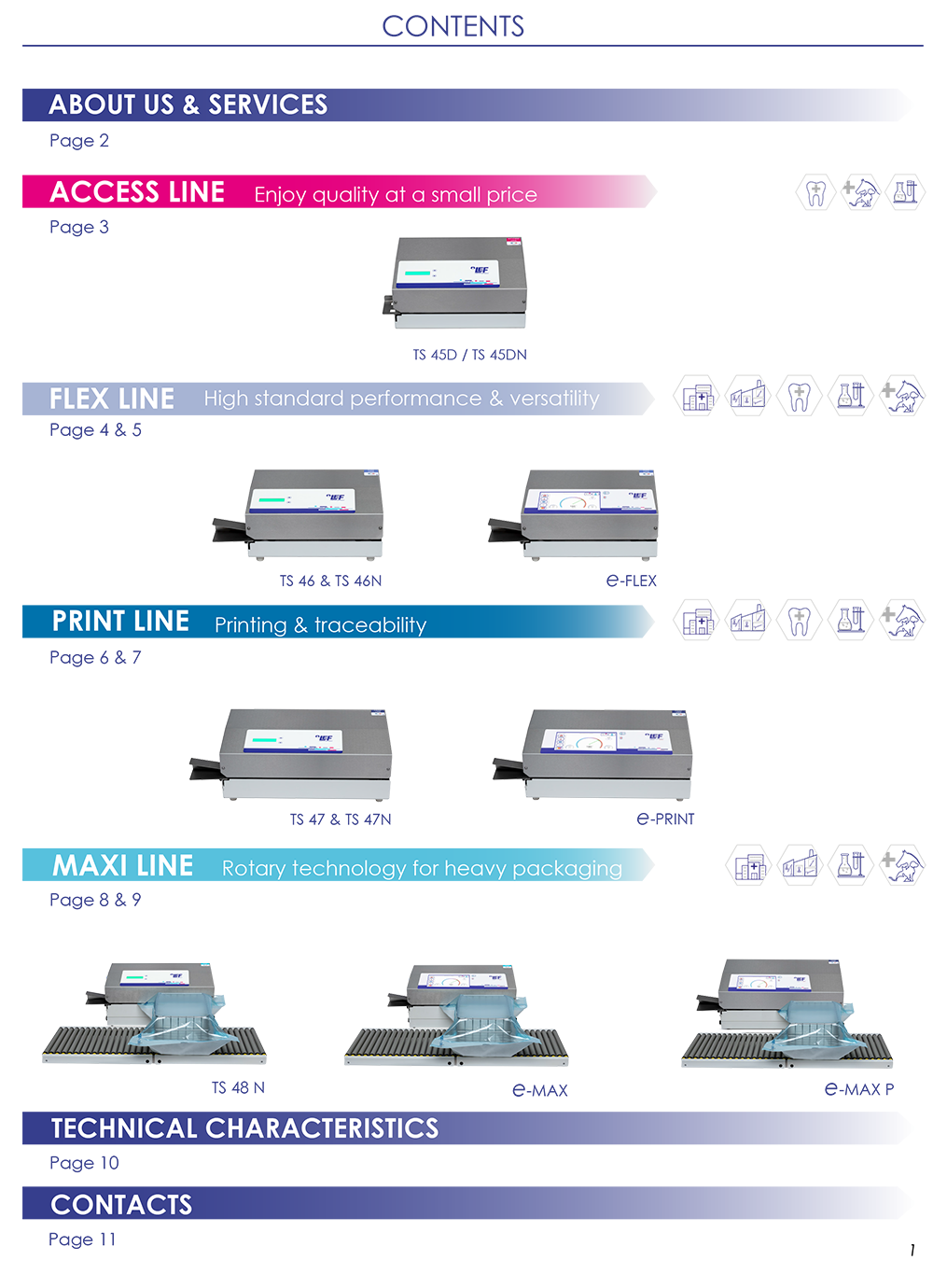

HEAT SEALERS PRINT LINE

Printing & traceability

TS 47 / TS 47N

- Amazingly easy handling

- Provided with a bar code editing software and SCANNER

- Perfectly clear 1 line printing

- Fits all types of pouches (steam, Tyvek®, Ultra®, OE, alu…)

- Protection of the printing mechanism

- 304L stainless steel hood

e-PRINT

- A wide and intuitive colour touch screen

- Provided with a bar code editing software and SCANNER

- 4 pre-set temperatures

- (LAN-ETHERNET / USB/ PRINTER)

- Traceability options available (USB / AUTO-TEST)

- Operational Qualification (OQ) included

.

Heat sealers PRINT LINE

The PRINT LINE range offers to CSSD units the best of technology, while remaining amazingly easy to use. Its barcode editing software allows a perfectly readable 1 line printout of the data on the pouches.

Technical characteristics

- Standards : CE / CEM / EN 868-5 / DIN 58953-7 for all the range, ISO 11607-2 (TS 47N / e-PRINT).

- Sealing: 15 mm width / flat and full weld for better checking, unlimited sealing length.

- Display: 1 line LCD (TS 47 / 47N), colour touch screen (e-PRINT).

- Temperature: 20-230C° with a 2% regulation tolerance on the TS 47 / 47N, 1% on the e-PRINT.

- USB output (e-PRINT).

- Software for personalized barcode editing.

- Barcode scanner (e-PRINT).

- Multifunction intuitive menu (graphics, counters, informative messages, multilingual, alphanumeric keyboard…) on e-PRINT.

- Adjustable pouches guide (0-30 mm from edge).

- Integrated digital maintenance notebook (e-PRINT).

- 5 pre-set temperatures (e-PRINT).

- Seals every kind of pouches (steam, Tyvek®, OE, alu, Ultra®,…).

- Starts automatically when the set temperature is reached.

- Environmentally responsible: automatic start and stop by photocell.

- Safety: critical parameters control complying to ISO 11607-2 standard (temperature & pressure) on TS 47N / e-PRINT.

- Automatic stop if critical parameters exceed limits (TS 47N / e-PRINT)

- Calibration certificate (COFRAC att.) on the e-PRINT.

Accessories

- Stainless steel front support tray (700 x 300 x 60 mm).

- Roll conveyor support tray (800 x 300 x 60 mm).

- Automatic self-test for critical parameters ISO 11067-2 with control receipt editing (AUTO-TEST).

- Sealings logs backup for ISO 11607-2 (USB)